Customized design Electric Pipeline heaters for heating industrial waste gas

Product Introduction

Electric Pipeline heaters for heating industrial waste gas is an efficient and compact electric heating device directly installed on pipelines. Its core task is to accurately and quickly heat the industrial waste gas flowing in the pipeline to meet the temperature conditions required for subsequent process treatments (such as catalytic reduction, desulfurization and denitrification), or to ensure that waste gas emissions meet environmental standards (to prevent the formation of white smoke and acid mist).

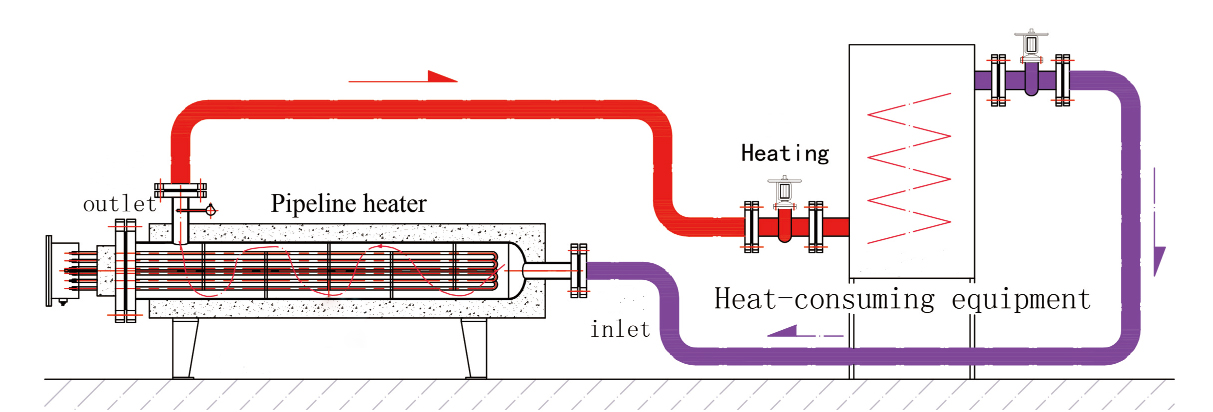

Working principle

Pipeline electric heater is a device that consumes electrical energy to convert it into thermal energy for heating materials that need to be. During operation, the low-temperature fluid medium enters its inlet under pressure, flows through the specific heat exchange channels inside the electric heating vessel, and follows path designed based on fluid thermodynamics principles, carrying away the high-temperature heat energy generated by the electric heating elements, thus increasing the temperature of the heated medium The outlet of the electric heater obtains the high-temperature medium required by the process. The internal control system of the electric heater automatically regulates the output power of the heater according to the temperature sensor signal at the outlet, maintaining a uniform temperature of the medium at the outlet; when the heating element overheats, the independent over protection device of the heating element immediately cuts off the heating power supply, preventing the heating material from overheating, causing coke, deterioration, and carbonization, and severe cases, causing the heating element to burn out, effectively extending the service life of the electric heater.

Product Advantage

1.Accurate temperature control: PID intelligent control is adopted, with high temperature control accuracy (up to ±1℃) and fast response speed.

2.High thermal efficiency: Directly heating the medium, the heat energy is concentrated in the pipeline, and with good insulation, the thermal efficiency can usually reach over 95%.

3.Compact structure, easy installation: can be directly connected by flange or inserted into pipelines, without the need for complex combustion systems and flues.

4.High degree of automation: easy to integrate with central control systems such as PLC , achieving fully automatic operation, remote monitoring, and interlocking protection.

5.Pollution free: Pure electric heating, no combustion products, clean and environmentally friendly.

6.Fast start-up: Compared to steam or hot oil heating, electric heaters can start and stop quickly.

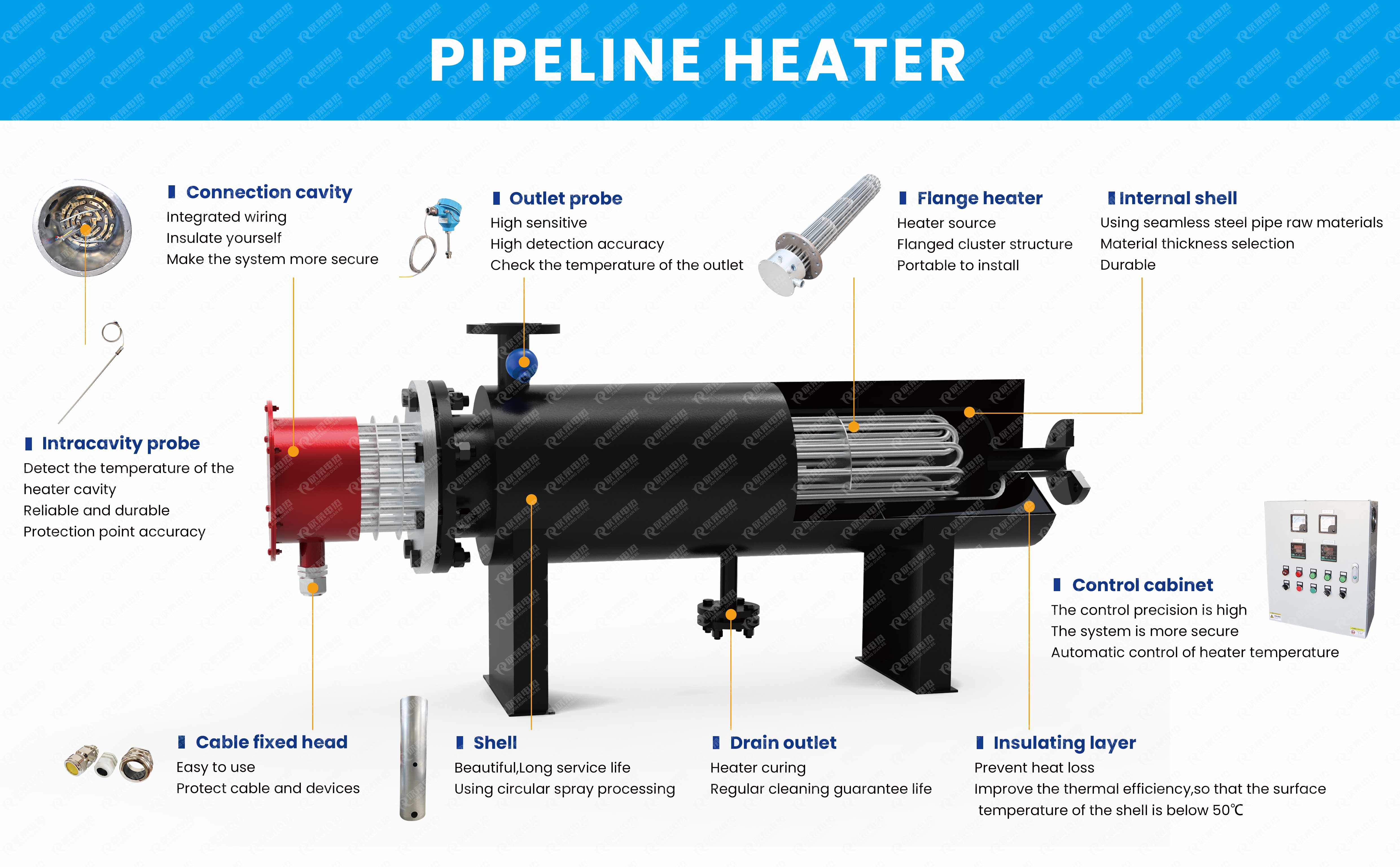

Product details display

The air circulation pipeline heater is composed of two parts: body and control system.Electric heating element generates heat: The electric heating element in the heater is the core part of generating heat. When an electric current passes through these elements, they generate a lot of heat.

Forced convection heating: When nitrogen or other medium passes through the heater, the blower is used to force convection, so that the medium flows and passes through the heating element. In this way, the medium, as a heat carrier, can effectively absorb heat and transfer it to the system that needs to be heated.

Temperature control: The heater is equipped with a control system including temperature sensor and PID controller. These components work together to automatically adjust the output power of the heater according to the outlet temperature, ensuring that the medium temperature is stable at the set value.

Overheating protection: In order to prevent overheating damage to the heating element, the heater is also equipped with overheating protection devices. As soon as overheating is detected, the device immediately cuts off the power supply, protecting the heating element and the system.

Product feature

- 1.Efficient and energy-saving: Electric energy is directly converted into thermal energy with high conversion efficiency (usually>95%). Good insulation design further reduces heat loss.

2.Accurate temperature control: PID control can achieve temperature control accuracy of ± 1 ° C , meeting strict process requirements.

3.Quick response: Electric heating starts quickly and the temperature rise and fall rate is relatively fast.

4.Clean and environmentally friendly: No combustion process, no exhaust gas, smoke or flames are generated, and the working environment is clean.

5.Easy to automate: Easy to integrate into PLC/DCS systems for remote monitoring and automated control.

6.Relatively easy to install: usually connected by flange and connected to the pipeline directly.

7.Flexible design: The power, size, and structure (such as explosion-proof type) can be customized according to gas flow rate, temperature rise requirements, pipeline size, pressure, gas composition, etc.

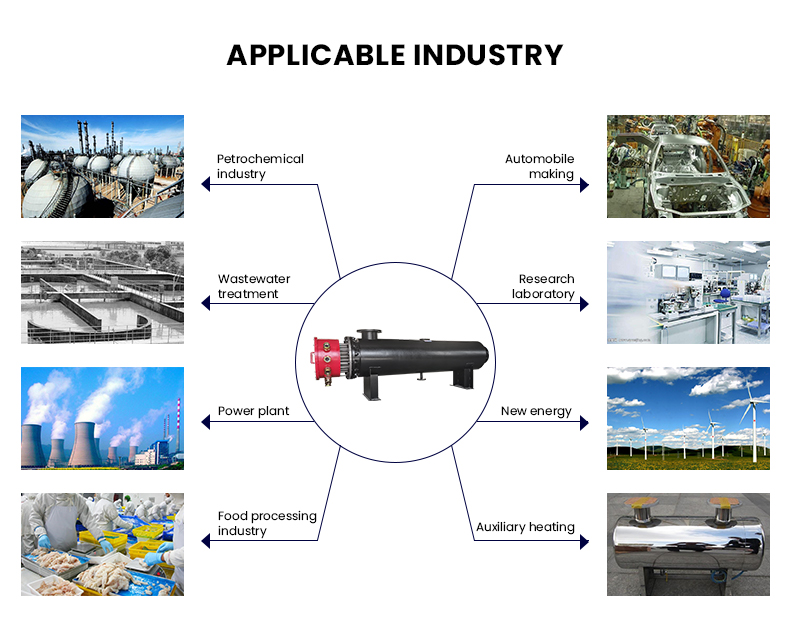

Product application

Pipeline inline air heaters are widely used in many application scenarios, like:

Chemical and Petrochemical: Heating process gases (such as nitrogen, hydrogen, argon, carbon dioxide, cracking gas, reaction gas), preventing gas condensation, preheating before gas desulfurization and denitrification, etc.

Oil and natural gas: heating natural gas (antifreeze, depressurization and anti icing), associated gas, flare gas, pipeline heating after liquefied petroleum gas (LPG) gasification, natural gas dehydration/pre metering heating, etc.

Electricity: Heating boiler air (primary air, secondary air), flue gas reheating of desulfurization system, etc.

Environmental protection: Preheating of exhaust gas in VOC waste gas treatment (catalytic combustion, RTO/RCO).

Laboratory: Precise control of experimental gas temperature.

And etc....

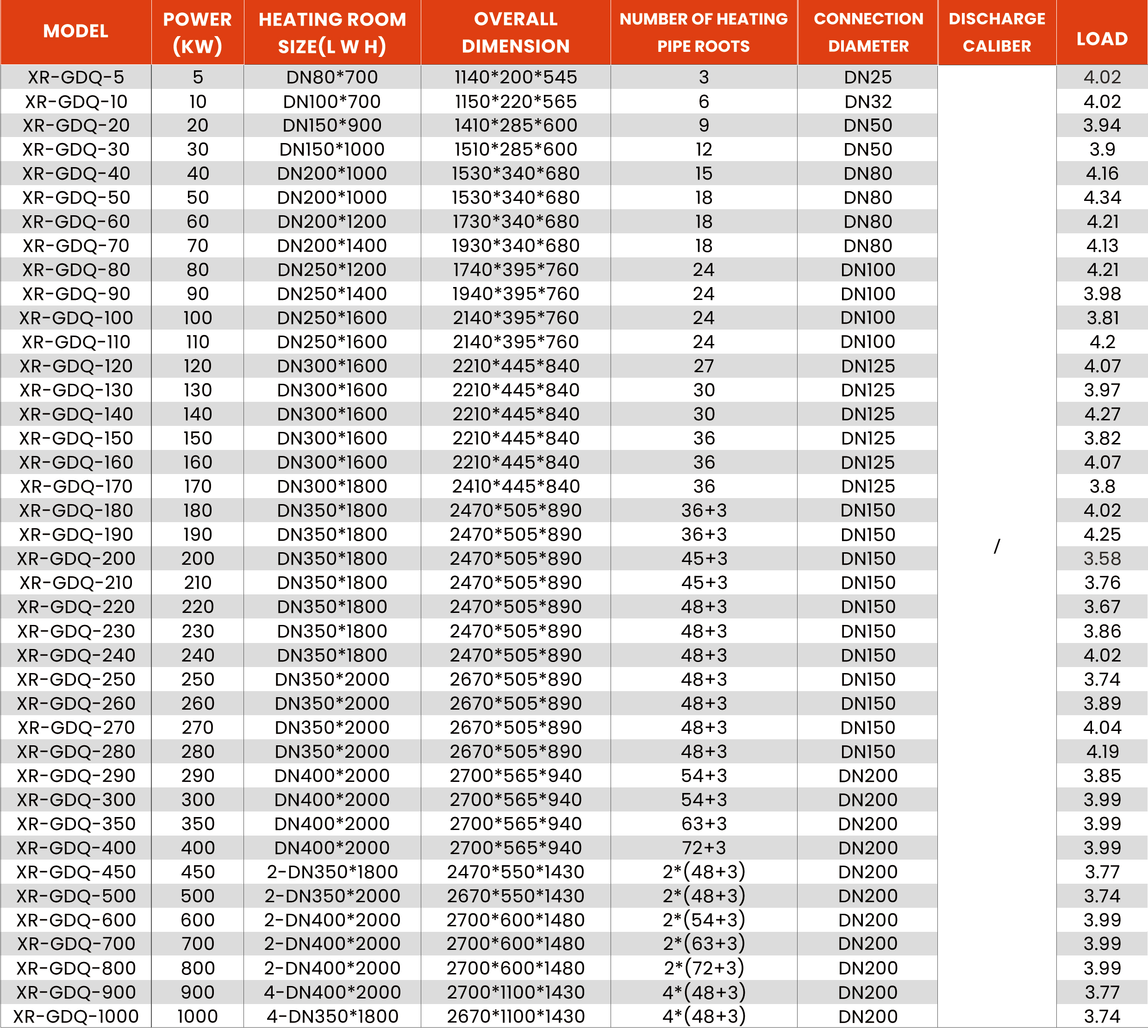

Technicial Specifications

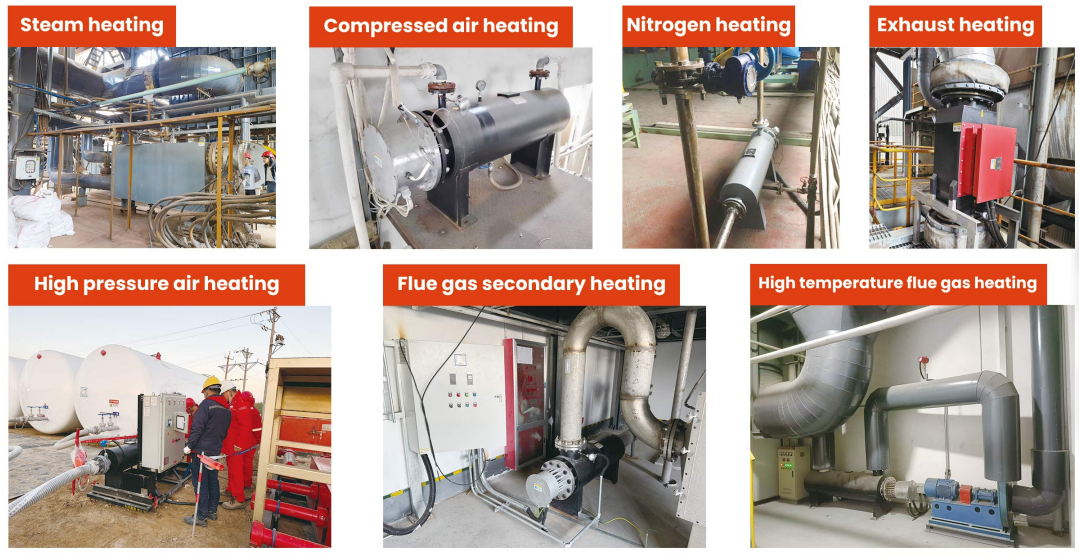

Customer use case

Certificate and qualification

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services