Industrial electric customized pipeline heater for water heating

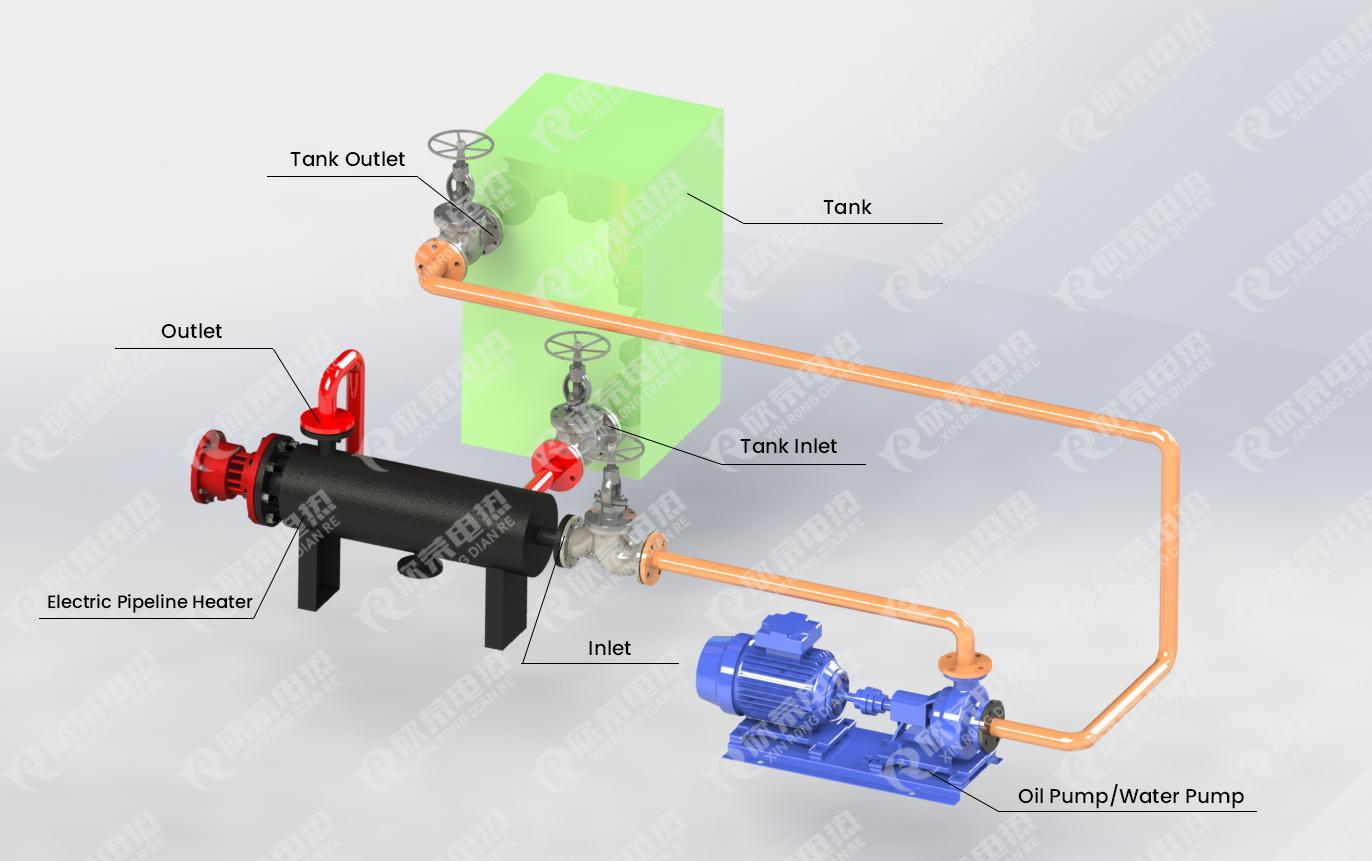

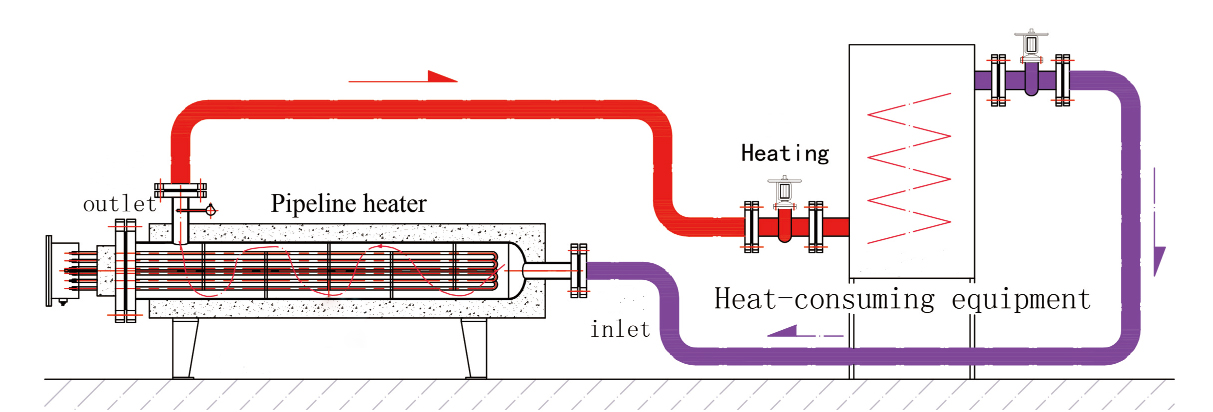

Working principle

Pipeline electric heater is a device that consumes electrical energy to convert it into thermal energy for heating materials that need to be. During operation, the low-temperature fluid medium enters its inlet under pressure, flows through the specific heat exchange channels inside the electric heating vessel, and follows path designed based on fluid thermodynamics principles, carrying away the high-temperature heat energy generated by the electric heating elements, thus increasing the temperature of the heated medium The outlet of the electric heater obtains the high-temperature medium required by the process. The internal control system of the electric heater automatically regulates the output power of the heater according to the temperature sensor signal at the outlet, maintaining a uniform temperature of the medium at the outlet; when the heating element overheats, the independent over protection device of the heating element immediately cuts off the heating power supply, preventing the heating material from overheating, causing coke, deterioration, and carbonization, and severe cases, causing the heating element to burn out, effectively extending the service life of the electric heater.

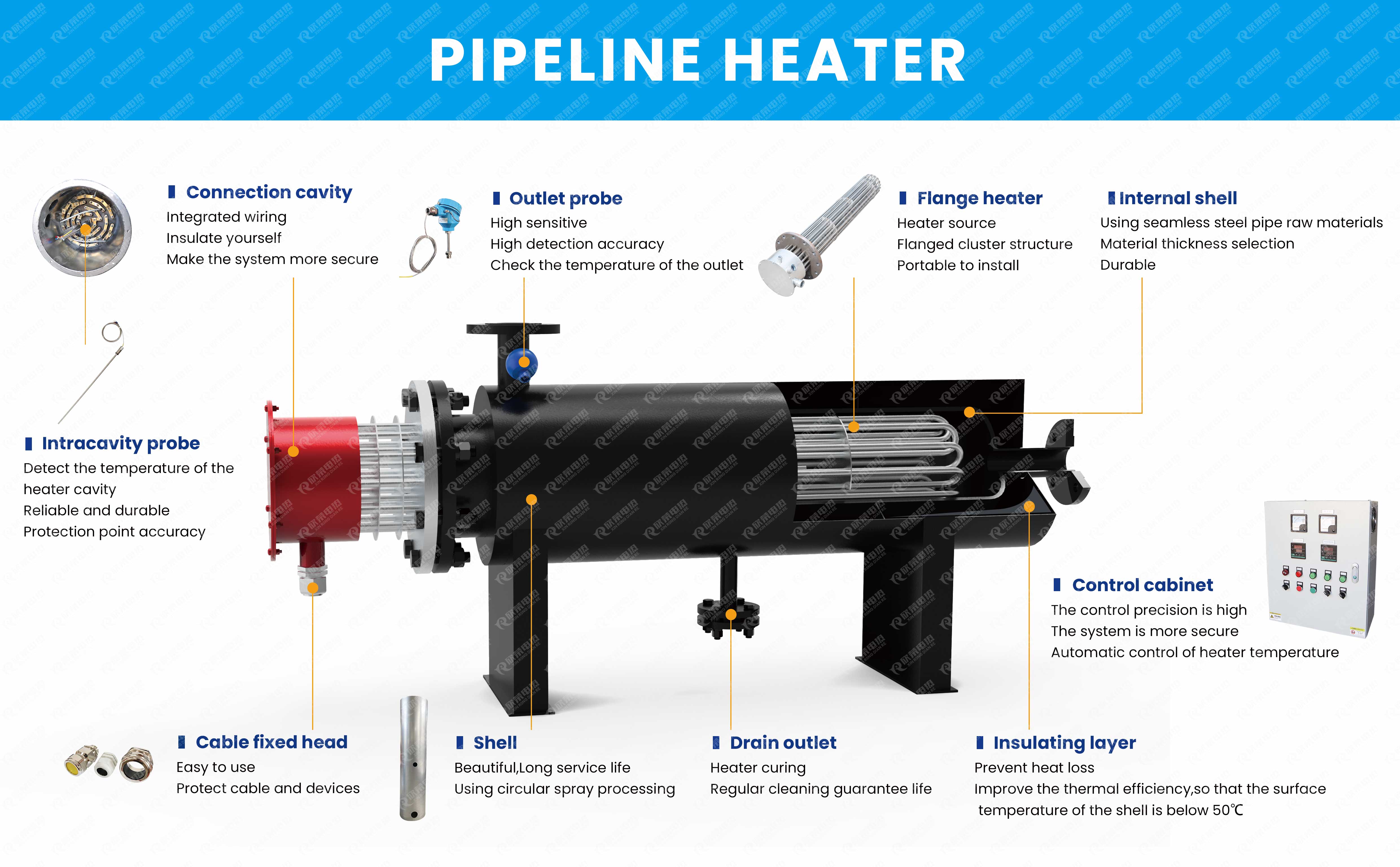

Product details display

The heating element adopts nickel chromium alloy electric heating wire as the heating element, filled with high-purity magnesium oxide powder insulation and thermal conductivity layer, and the outer layer is wrapped with stainless steel (304/316L or others) or carbon steel sheath, which has corrosion resistance and scale resistance characteristics.

The heating element adopts a tubular design, which supports direct insertion into pipelines or rapid heating of the flowing medium through flange connections.

Integrated components, flange connection: standard stainless steel flange, compatible with DN80-DN500 pipe diameter, supports quick installation and sealing maintenance.

Insulation layer: The outer layer is wrapped with aluminum silicate cotton or rock wool material to reduce heat loss, and the thermal efficiency can reach over 90%.

Temperature control system: Integrated PT100 or K-type thermocouple, combined with thyristor/solid-state relay module to achieve ± 1 ℃ precision adjustment.

Working condition application overview

1) Overview of sewage heating pipeline electric heater

The electric heater is a kind of equipment which is mainly used for sewage heating in sewage treatment project. The electric heater converts electrical energy into heat energy to realize the heating effect of the sewage heating pipe and improve the efficiency and quality of the sewage treatment process.

2) Working principle of electric heater of sewage heating pipeline

The working principle of the electric heater in the sewage heating pipeline can be divided into two parts: electric energy conversion and heat transfer.

1. Electric energy conversion

After the resistance wire in the electric heater is connected to the power supply, the current through the resistance wire will produce energy loss, which is converted into heat energy, heating the heater itself. The temperature of the heater surface increases with the increase of the current, and eventually the heat energy of the heater surface is transmitted to the sewage pipe that needs to be heated.

2. Heat conduction

The electric heater transfers heat energy from the surface of the heater to the surface of the pipe, and then gradually transfers it along the wall of the pipe to the sewage in the pipe. The process of heat conduction can be described by the heat conduction equation, and its main influencing factors include pipe material, pipe wall thickness, thermal conductivity of heat transfer medium, etc.

3) Summary

The electric heater converts electrical energy into heat energy to realize the heating effect of the sewage heating pipeline. Its working principle includes two parts: electric energy conversion and thermal heat transfer, of which thermal heat transfer has many influencing factors. In practical applications, the appropriate electric heater should be selected according to the actual situation of the heating pipeline, and reasonable maintenance should be carried out.

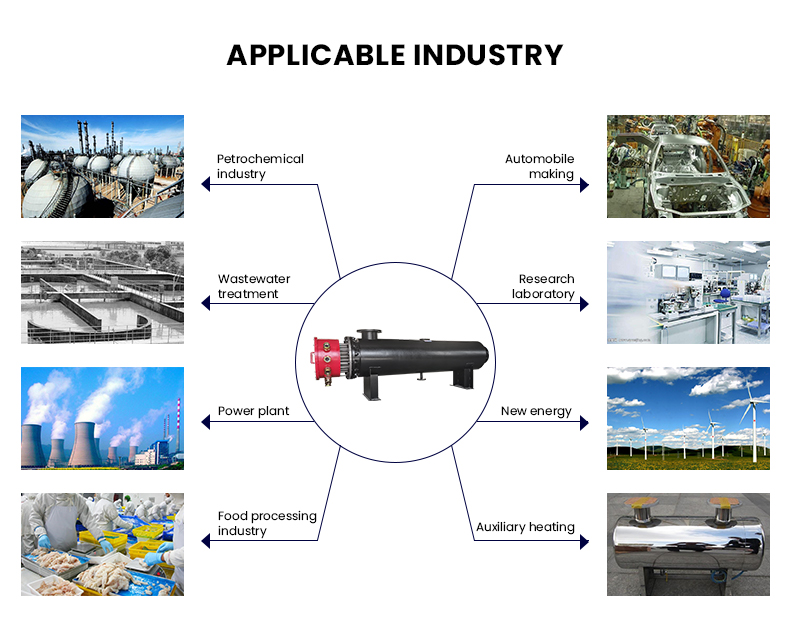

Product application

Pipeline heater widely used in aerospace, weapons industry, chemical industry and colleges and universities and many other scientific research and production laboratory. It is especially suitable for automatic temperature control and large flow high temperature combined system and accessory test, the heating medium of the product is non-conductive, non-burning, non-explosion, no chemical corrosion, no pollution, safe and reliable, and the heating space is fast (controllable).

Product Features

1.Efficient and energy-saving: With a thermal efficiency of over 95%, electrical energy is directly converted into thermal energy without any intermediate losses. It can be temperature controlled in zones or operated in different time periods to reduce energy consumption.

2.Safe and reliable: Multiple protection mechanisms to avoid risks such as dry burning and electrical leakage.

3.Flexible installation: Supports horizontal or vertical installation to adapt to different pipeline layouts. Modular design facilitates expansion or replacement of components.

4.Environmentally friendly and pollution-free: No combustion exhaust emissions, meeting environmental protection requirements.

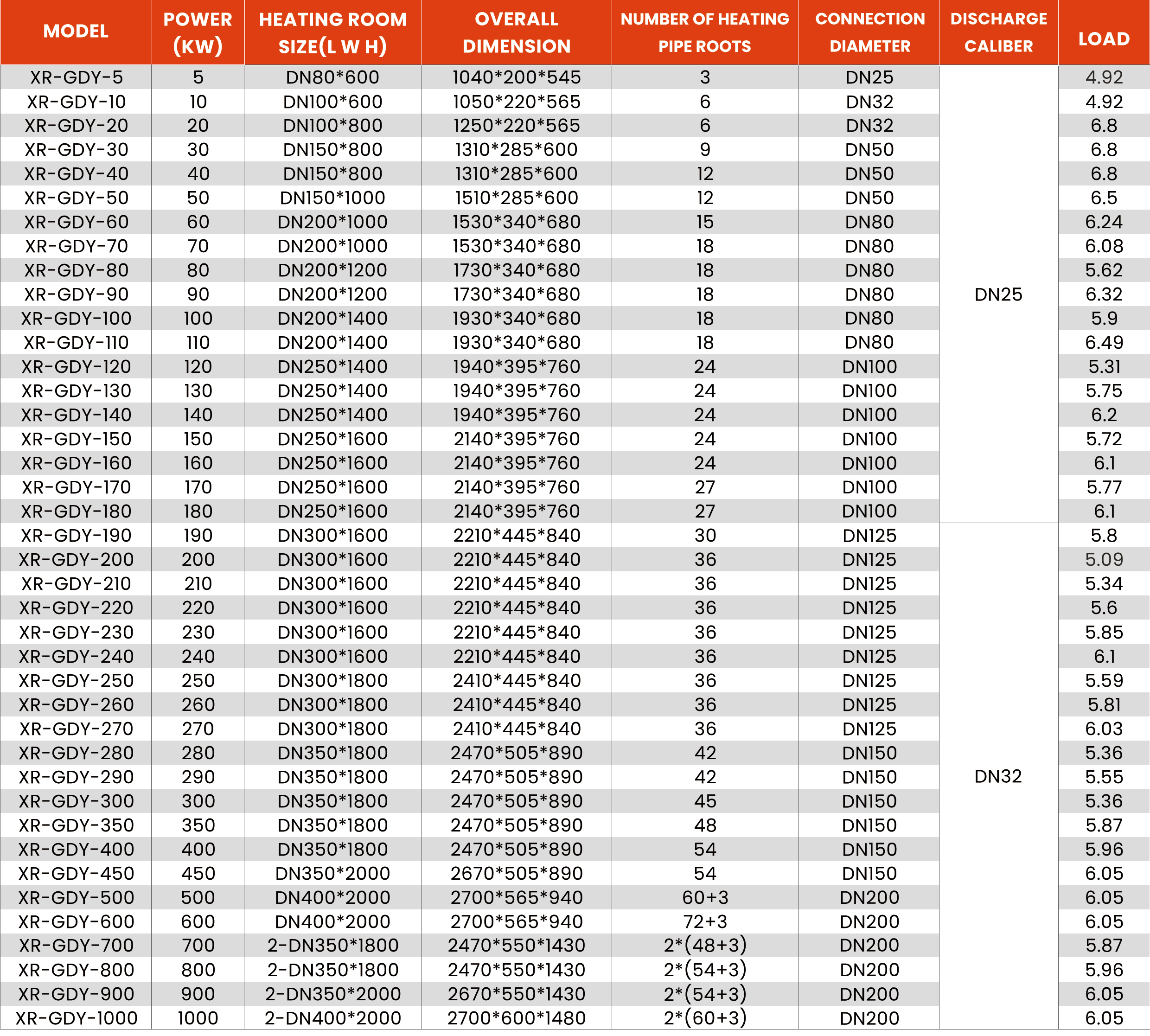

Technicial Specifications

Customer use case

Fine workmanship, quality assurance

We are honest, professional and persistent, to bring you excellent products and quality service.

Please feel free to choose us, let us witness the power of quality together.

Certificate and qualification

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services