- 1. Heating medium

Water: ordinary industrial circulating water, no special requirements.

Corrosive liquids (such as acid, alkali, salt water): stainless steel (316L) or titanium heating tubes are required.

High viscosity liquids (such as oil, thermal oil): high power or stirring heating system is required.

2. Heater type selection

(1) Immersion electric heater (directly inserted into the water tank/pipeline)

Applicable scenarios: water tank, storage tank, reactor heating.

Advantages: simple installation and low cost.

Disadvantages: scale needs to be cleaned regularly, not suitable for high pressure systems.

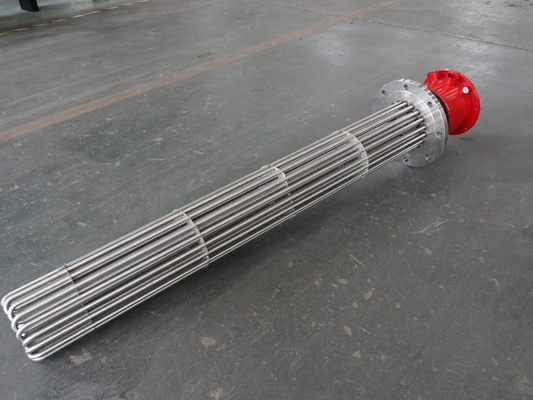

(2) Flange electric heater (flange connection)

Applicable scenarios: high pressure, large flow circulation system (such as boiler water supply, chemical reactor).

Advantages: high pressure resistance (up to 10MPa or more), easy maintenance.

Disadvantages: high price, need to match flange interface

(3) Pipeline electric heater (connected in series in the pipeline)

Applicable scenarios: closed circulation system (such as HVAC, industrial hot water circulation).

Advantages: uniform heating, can be precisely adjusted with the temperature control system.

Disadvantages: the pressure bearing capacity of the pipeline must be considered during installation.

(4) Explosion-proof electric heater (Exd/IICT4 certified)

Applicable scenarios: chemical, petroleum, natural gas and other explosive environments.

Features: fully enclosed explosion-proof design, in compliance with ATEX/IECEx standards.

If you want to know more about our product, please contact us!

Post time: Jun-16-2025