Working principle

Basic principle: By converting electrical energy into heat energy, heat is generated through high-temperature resistance wires evenly distributed inside a seamless stainless steel tube. When current passes through, the heat diffuses to the surface of the metal tube through crystalline magnesium oxide powder filled in the gap, and is then transferred to the heated air, thereby achieving heating of the air.

Structural Assistance Principle: The heaterchamber is equipped with multiple baffles (deflectors) to guide the flow of gas, prolong the residence time of gas in the chamber, enable the gas to be fully heated, improve heat exchange efficiency, and make gas heating more uniform.

Characteristic

- High temperature heating capability: It can heat the air to a very high temperature, up to 850 ℃, while the shell temperature is relatively low, usually only around 50 ℃, which not only meets the high temperature heating requirements but also ensures the safety of the external equipment.

- Efficient and energy-saving: The thermal efficiency can reach 0.9 or above, effectively converting electrical energy into thermal energy, reducing energy loss, and lowering operating costs.

- Rapid heating and cooling: The heating and cooling rate is fast, up to 10 ℃/S, and the adjustment is fast and stable. There will be no temperature control drift caused by the controlled air temperature leading or lagging, which is very suitable for automatic control application scenarios.

- Good mechanical performance: The heating element is made of specially made alloy material, which has better mechanical performance and strength than other heating elements under the impact of high-pressure air flow. It is more superior for systems and accessory tests that require continuous air heating for a long time.

- Long service life: Without violating the usage regulations, it is durable and has a service life of several decades, reducing the frequency of equipment replacement and maintenance.

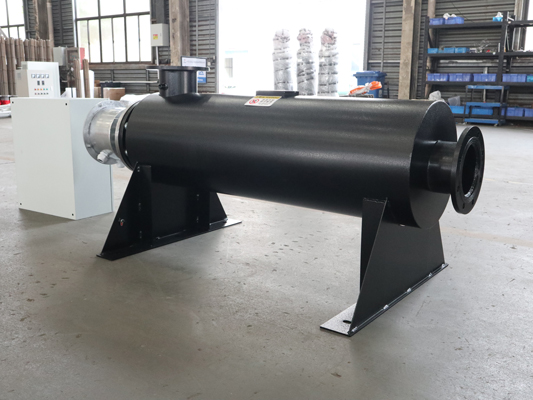

- Small volume of clean air: During the heating process, there will be no pollution to the air, ensuring the cleanliness of the heated air. At the same time, the overall volume of the equipment is small, making it easy to install and arrange.

Key selection points

- Power selection: Determine the appropriate heater power through thermal balance calculation based on the required air flow rate, initial temperature, and target temperature to ensure that the heating demand is met.

- Material requirements: Choose the appropriate heater material based on the usage environment and the properties of the heated gas. For example, stainless steel material is suitable for general corrosive environments, while special alloy materials may need to be selected for high temperature and highly corrosive gases.

- Control mode: Select the appropriate control mode based on actual application requirements, such as manual control, semi-automatic control, or fully automatic control, to achieve precise control of heating temperature and operating status.

- Safety protection function: It should have safety protection functions such as overheating protection, overcurrent protection, and leakage protection to ensure the safety of the equipment during operation and prevent accidents.

If you want to know more about our product, please contact us!

Post time: May-16-2025