Pipeline Heater for Molten Salt

Product Overview

The Pipeline Heater for Molten Salt is a high-performance thermal equipment engineered to efficiently heat molten salt in industrial pipelines, ensuring precise temperature control and stable heat transfer for critical processes. Designed for extreme operating conditions, this heater integrates advanced heating technology with robust materials to meet the demands of molten salt applications.

Technical Specifications

|

Parameter |

Specification |

| Power Range | 5 kW – 1000 kW |

| Operating Voltage | 380V/440V/660V (three-phase) |

| Temperature Range | 200°C – 800°C |

| Pipe Diameter | DN50 – DN300 (customizable) |

| Heating Element Type | Sheathed tubular (Inconel 825) |

| Control Accuracy | ±1°C |

| Protection Rating | IP65 (heater body), IP54 (control panel) |

| Certification | CE, ISO 9001 |

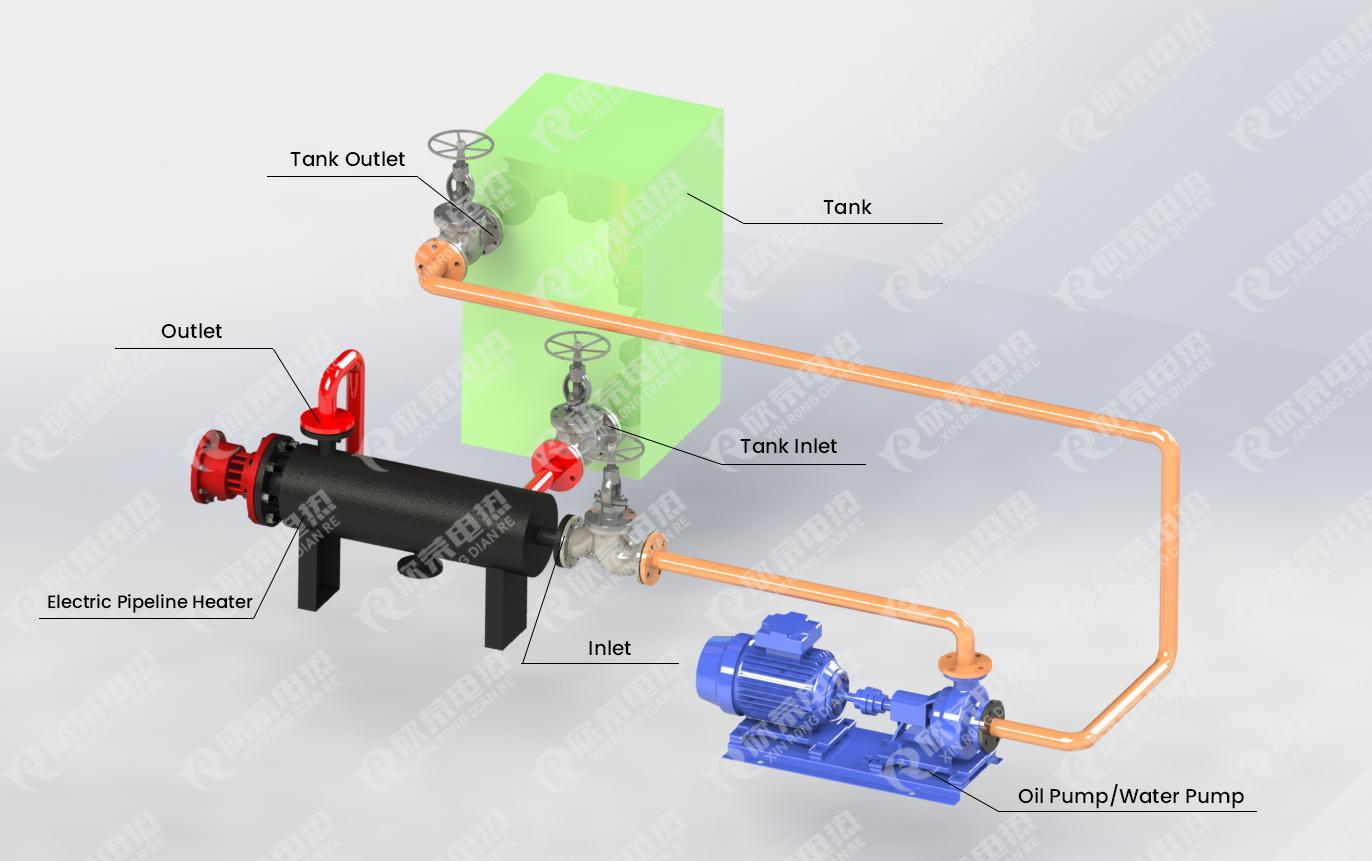

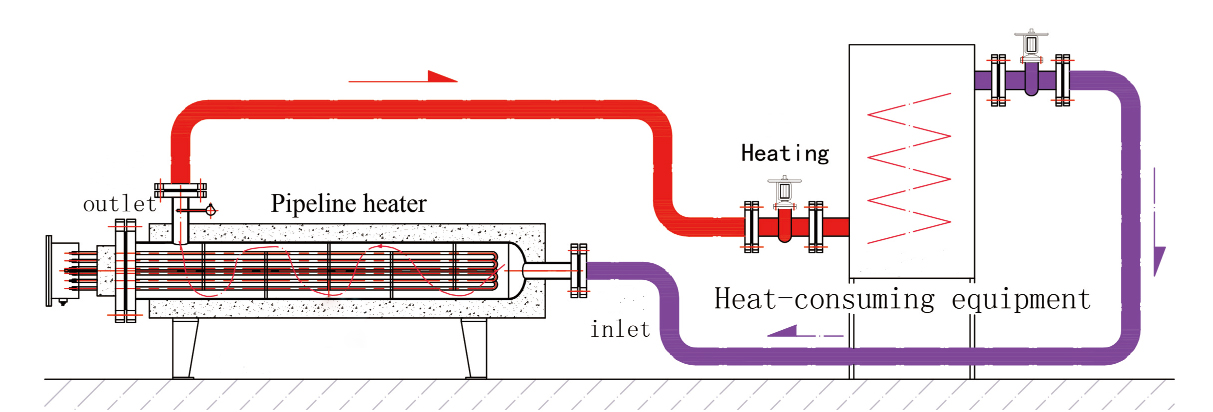

Working principle

Pipeline electric heater is a device that consumes electrical energy to convert it into thermal energy for heating materials that need to be. During operation, the low-temperature fluid medium enters its inlet under pressure, flows through the specific heat exchange channels inside the electric heating vessel, and follows path designed based on fluid thermodynamics principles, carrying away the high-temperature heat energy generated by the electric heating elements, thus increasing the temperature of the heated medium The outlet of the electric heater obtains the high-temperature medium required by the process. The internal control system of the electric heater automatically regulates the output power of the heater according to the temperature sensor signal at the outlet, maintaining a uniform temperature of the medium at the outlet; when the heating element overheats, the independent over protection device of the heating element immediately cuts off the heating power supply, preventing the heating material from overheating, causing coke, deterioration, and carbonization, and severe cases, causing the heating element to burn out, effectively extending the service life of the electric heater.

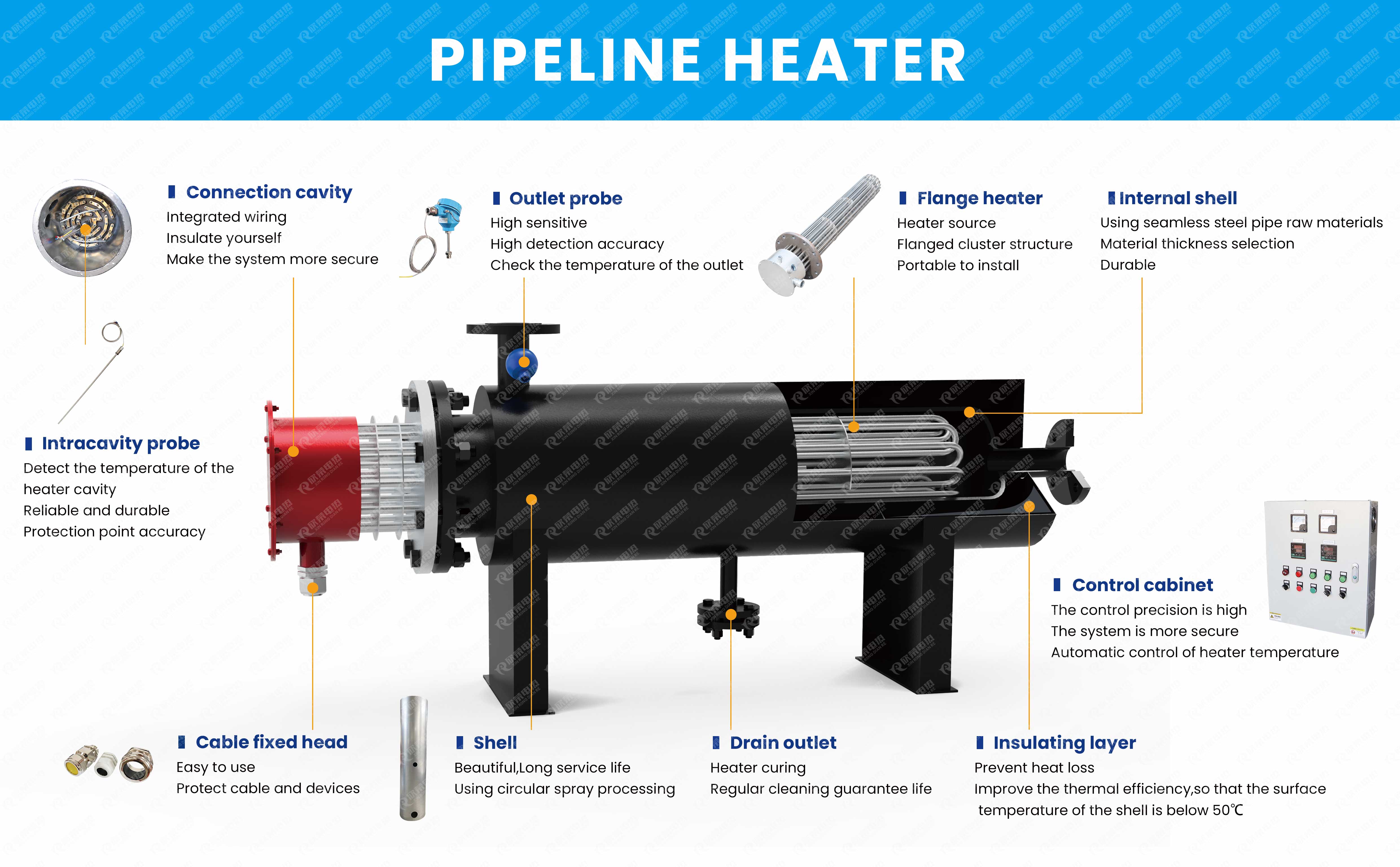

Product details display

1.Electricity conversion: external power source (usually industrial AC) is input into the heater control system.

2.Electric thermal conversion: Electric energy is converted into thermal energy through built-in electric heating elements.

3.Control cabinet: Real time monitoring of crude oil temperature through temperature sensors installed on pipelines (such as PT100 thermistor or K type thermocouple), and feedback of signals to the temperature controller. The controller intelligently adjusts the power supplied to the electric heating element based on the set target temperature (usually achieved through thyristor, solid-state relay, etc. for on-off or power regulation control), achieving precise and stable temperature maintenance.

Working condition application overview

1) Overview of sewage heating pipeline electric heater

The electric heater is a kind of equipment which is mainly used for sewage heating in sewage treatment project. The electric heater converts electrical energy into heat energy to realize the heating effect of the sewage heating pipe and improve the efficiency and quality of the sewage treatment process.

2) Working principle of electric heater of sewage heating pipeline

The working principle of the electric heater in the sewage heating pipeline can be divided into two parts: electric energy conversion and heat transfer.

1. Electric energy conversion

After the resistance wire in the electric heater is connected to the power supply, the current through the resistance wire will produce energy loss, which is converted into heat energy, heating the heater itself. The temperature of the heater surface increases with the increase of the current, and eventually the heat energy of the heater surface is transmitted to the sewage pipe that needs to be heated.

2. Heat conduction

The electric heater transfers heat energy from the surface of the heater to the surface of the pipe, and then gradually transfers it along the wall of the pipe to the sewage in the pipe. The process of heat conduction can be described by the heat conduction equation, and its main influencing factors include pipe material, pipe wall thickness, thermal conductivity of heat transfer medium, etc.

3) Summary

The electric heater converts electrical energy into heat energy to realize the heating effect of the sewage heating pipeline. Its working principle includes two parts: electric energy conversion and thermal heat transfer, of which thermal heat transfer has many influencing factors. In practical applications, the appropriate electric heater should be selected according to the actual situation of the heating pipeline, and reasonable maintenance should be carried out.

Product Advantages

-

-

- Customizable Design: Tailored to specific pipe sizes, power requirements, and process conditions, ensuring seamless integration into existing pipelines.

- Low Maintenance: Removable heating elements and modular construction simplify inspection and replacement, reducing downtime.

- Environmental Adaptability: Suitable for both indoor and outdoor installations, with corrosion-resistant components for harsh industrial environments.

- Cost-Effective Operation: High energy efficiency and long service life lower total cost of ownership over time.

-

Product Features

-

- High-Temperature Resistance: Constructed with nickel-based alloys and ceramic insulation, the heater withstands molten salt temperatures up to 800°C, ensuring long-term durability under thermal stress.

- Uniform Heat Distribution: Utilizes a helical heating element design with optimized watt density to prevent localized overheating, ensuring molten salt flows evenly without caking or solidification.

- Precise Temperature Control: Equipped with a PID control system and K-type thermocouple , enabling temperature accuracy within ±1°C, critical for maintaining molten salt viscosity and thermal efficiency.

- Energy Efficiency: Features low thermal inertia and rapid heat-up response, reducing energy consumption by minimizing heat loss through a double-layer insulation structure (aluminum silicate + stainless steel jacket).

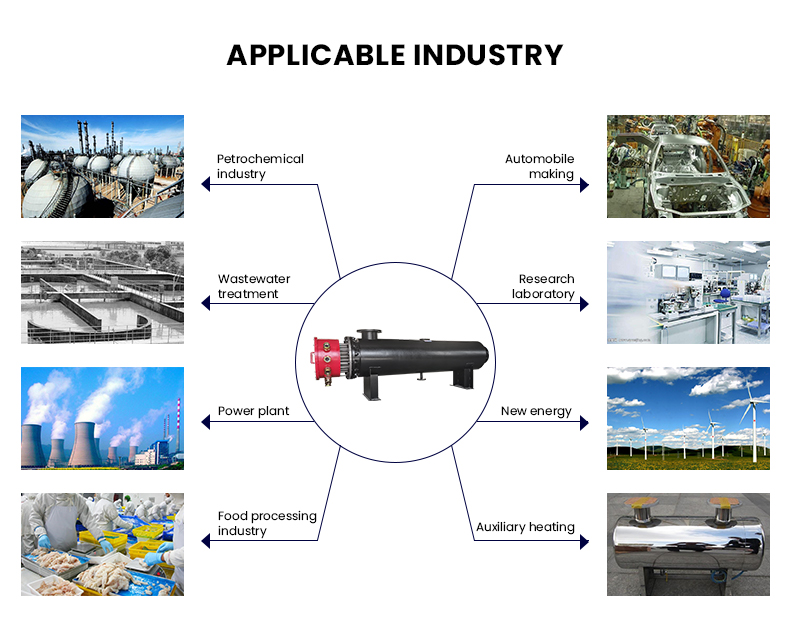

Product application

Pipeline heater is widely used in aerospace, weapons industry, chemical industry and colleges and universities and many other scientific research and production laboratory. It is especially suitable for automatic temperature control and large flow high temperature combined system and accessory test, the heating medium of the product is non-conductive, non-burning, non-explosion, no chemical corrosion, no pollution, safe and reliable, and the heating space is fast (controllable).

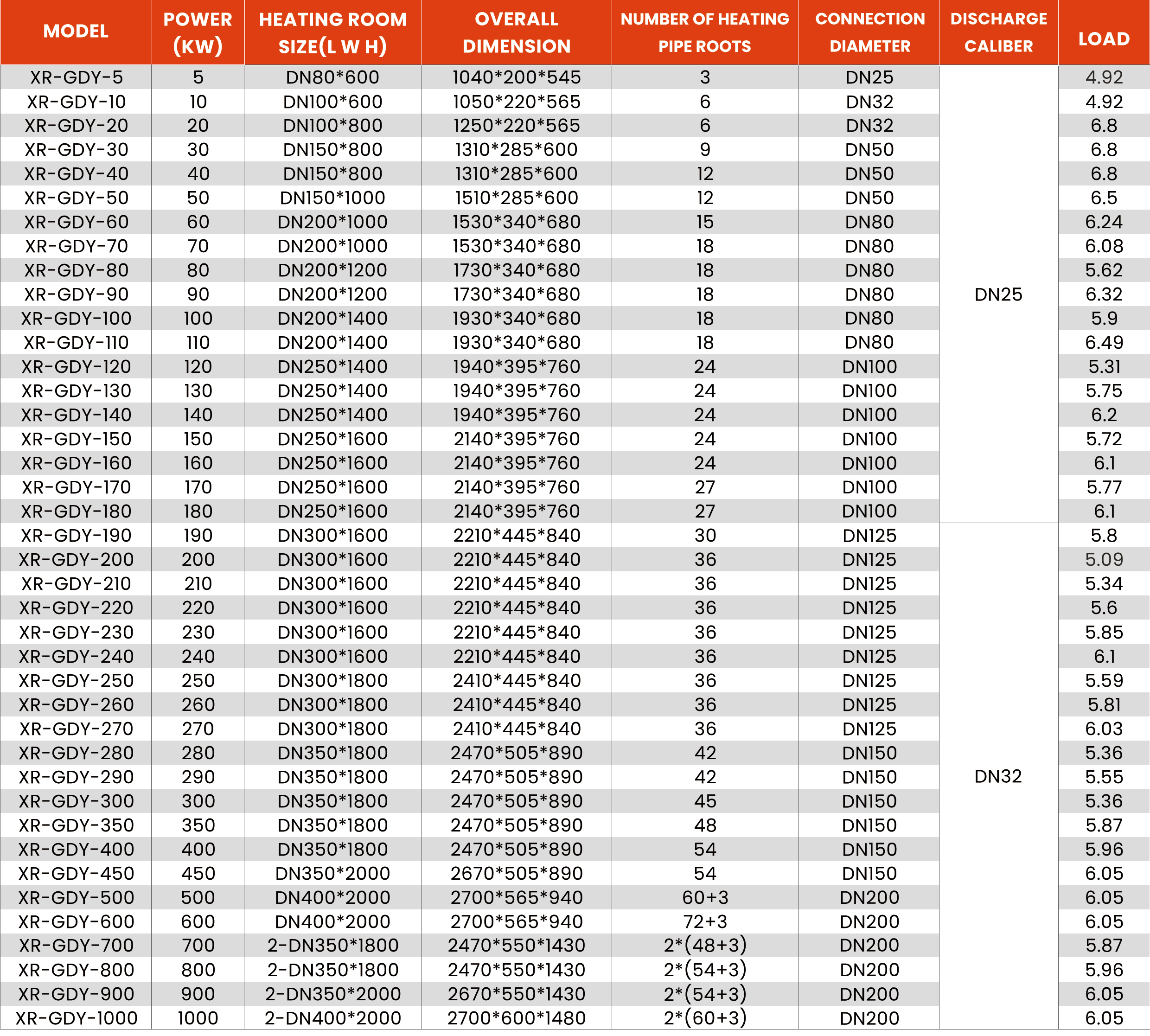

Technicial Specifications

Customer use case

Fine workmanship, quality assurance

We are honest, professional and persistent, to bring you excellent products and quality service.

Please feel free to choose us, let us witness the power of quality together.

Certificate and qualification

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services