Electric thermal oil heater

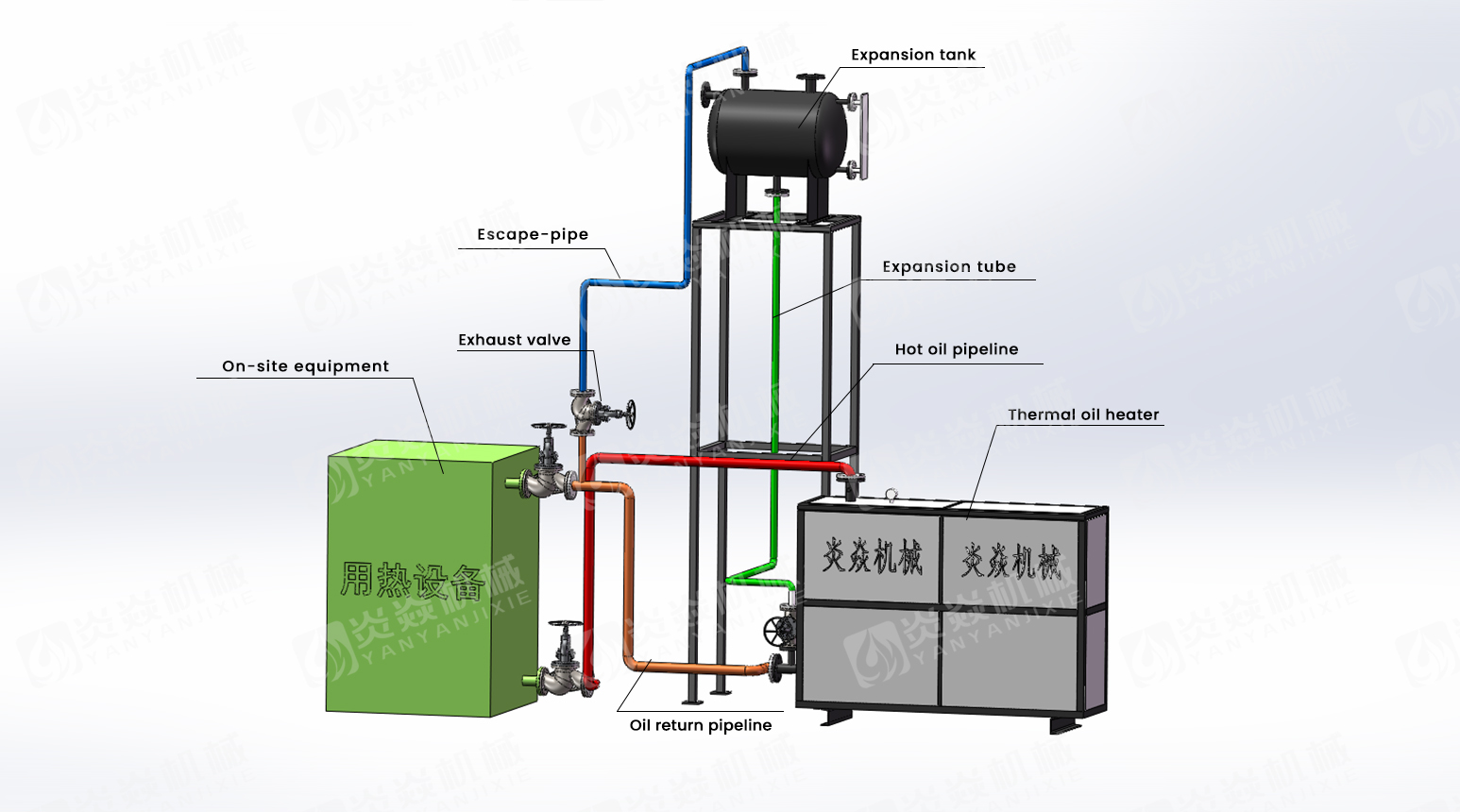

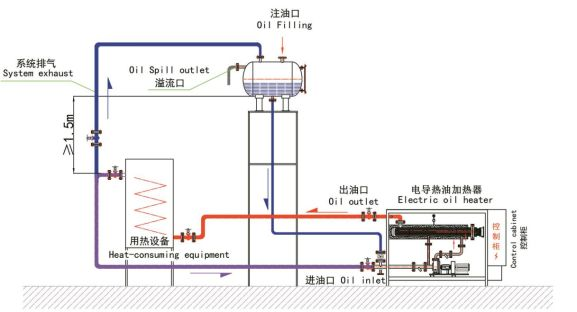

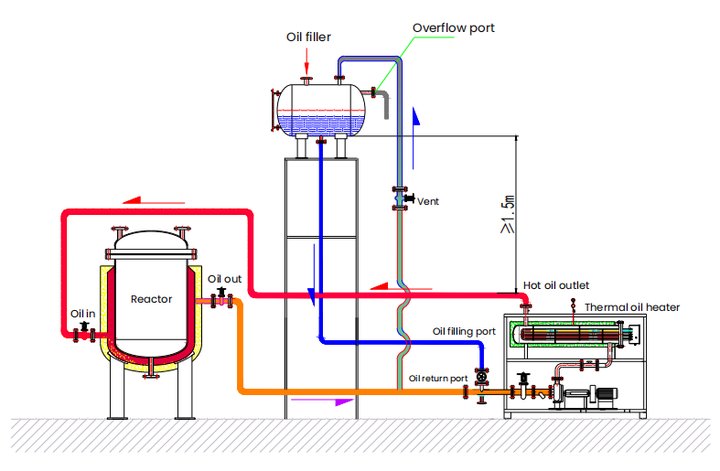

Working principle

For Electric thermal oil heater, heat is generated and transmitted by electric heating element immersed in thermal oil. With thermal oil as medium, circulation pump is used to force thermal oil to carry out liquid phase circulation and transfer heat to one or more thermal equipment. After unloading by the thermal equipment, Re-through the circulation pump, back to the heater, and then absorb heat, transfer to the heat equipment, so repeat, to achieve continuous transfer of heat, so that the temperature of the heated object rises, to meet the heating process requirements

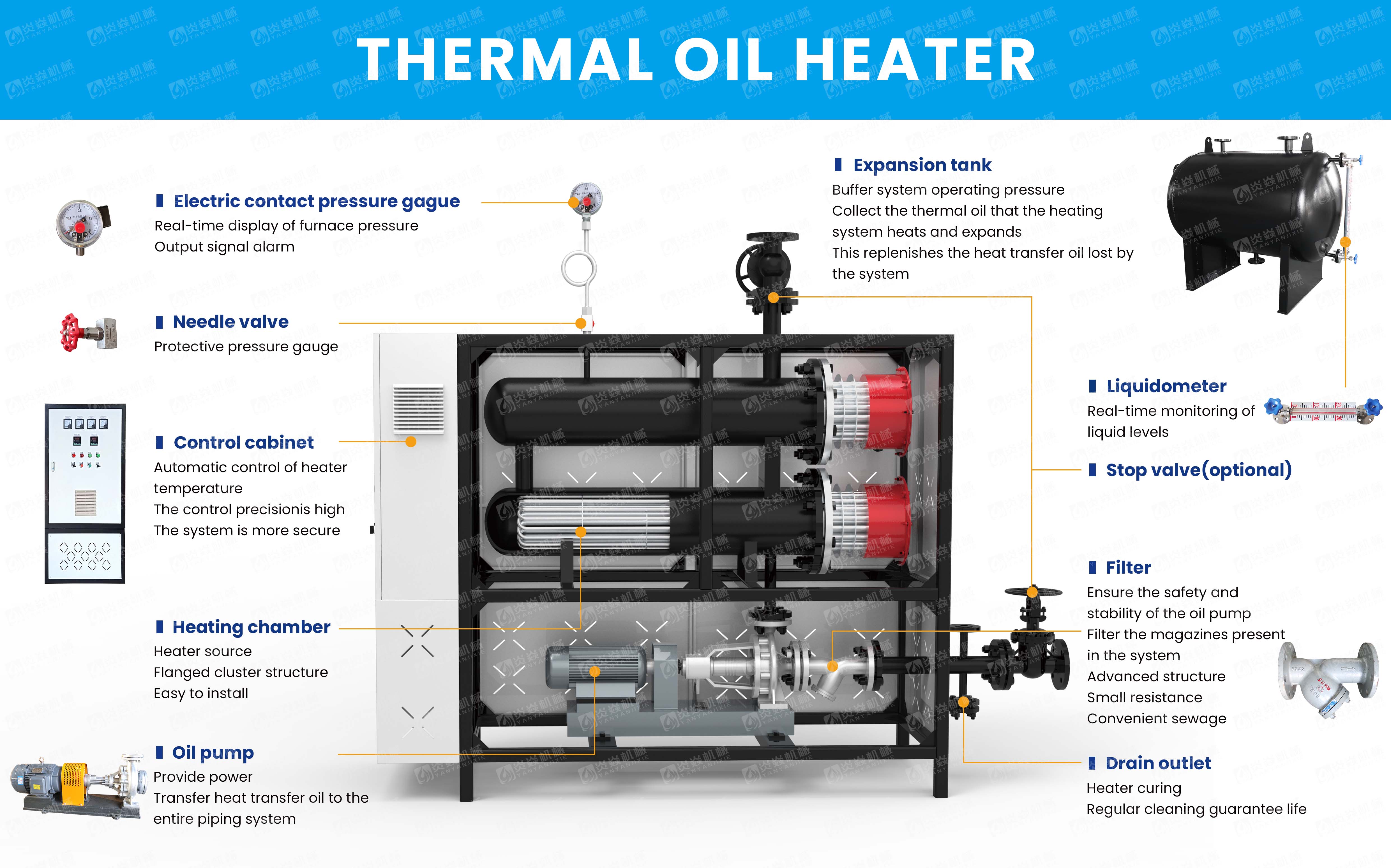

Product details display

Product advantage

1, with complete operation control, and safe monitoring device, can implement automatic control.

2, can be under lower operating pressure, obtain a higher working temperature.

3, the high thermal efficiency can reach more than 95%, the accuracy of temperature control can reach ±1℃.

4, the equipment is small in size, the installation is more flexible and should be installed near the equipment with heat.

Working condition application overview

1) Overview

Electric thermal oil heater is a commonly used industrial heat source equipment, its main function is to convert electric energy into heat energy, supply to the equipment or medium that needs to be heated in the industrial production process. Its working principle is relatively simple, but in the actual use of the process need to pay attention to some details in order to better play its advantages.

2) Heating method

The heating method of the organic heat carrier furnace is mainly through the heating tube resistance heating, the use of thermal resistance or thermocouple temperature sensors to monitor the temperature of the furnace body, and then through the electric control system to adjust the current size of the electric heater, so as to control the temperature of the furnace body.

3) Circulation mode

In order to ensure the full circulation of the heat carrier and make it uniformly heated, the electric heating organic heat carrier furnace usually adopts a circulation mode, that is, the heat carrier is circulated through the electric heating oil pump to achieve the purpose of uniform heating.

4) Use precautions

1. The gas in the heat carrier should be removed before heating in the electric heater to avoid explosion or foam phenomenon of the heat carrier.

2. Ensure the normal operation of circulating pumps and other equipment, so as not to cause the heat carrier to fail to circulate normally, resulting in uneven heating or high temperature of the heat carrier.

(3) When heating the electric furnace, the appropriate electric heater and control system should be selected according to the type of heat carrier and the use temperature to ensure the normal operation of the furnace.

4, the heat exchanger should be cleaned regularly during the use of the heating furnace, so as to avoid precipitation and scaling of the heat carrier during operation, affecting the heat transfer effect.

5) Conclusion

Electric heating organic heat carrier furnace is a commonly used industrial heat source equipment, its main principle is through resistance heating, the electric energy into heat energy supply to the industrial production process needs to heat the equipment or medium. By adopting the circulation mode, the heat carrier can be fully circulated and the purpose of uniform heating can be achieved. In the process of use, attention should be paid to the selection of heat carriers, the adjustment of the control system and the regular cleaning of the heat exchanger to ensure the safe, stable and efficient operation of the electric heating organic heat carrier furnace.

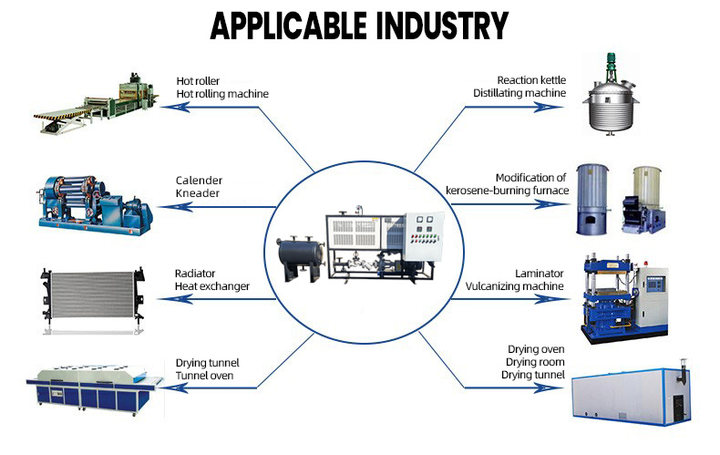

Product application

As a new type of special industrial boiler, which is safe, efficient and energy saving, low pressure and can provide high temperature heat energy, high temperature oil heater is being applied rapidly and widely. It is a high efficiency and energy saving heating equipment in chemical, petroleum, machinery, printing and dyeing, food, shipbuilding, textile, film and other industries.

Customer use case

Fine workmanship, quality assurance

We are honest, professional and persistent, to bring you excellent products and quality service.

Please feel free to choose us, let us witness the power of quality together.

Certificate and qualification

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services