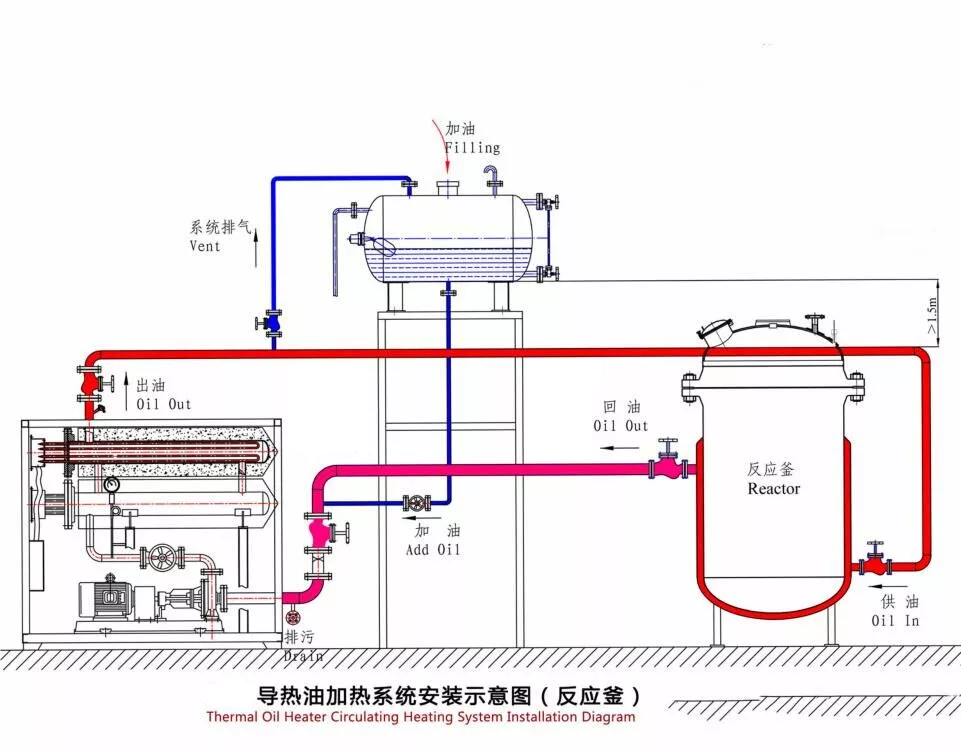

For the electric heating oil furnace, thermal oil is injected into the system through the expansion tank, and the inlet of thermal oil heating furnace is forced to circulate with a high head oil pump. An oil inlet and an oil outlet are respectively provided on the equipment, which are connected by flanges. The heat is generated and transmitted by the electric heating element immersed in the heat-conducting oil. The heat-conducting oil is used as the medium and the circulating pump is used to force the heat-conducting oil to circulate in the liquid phase. After the equipment is unloaded by the heating equipment, it passes through the circulating pump again, returns to the heater, absorbs heat, and transfers it to the heating equipment. In this way, the continuous transfer of heat is realized, the temperature of the heated object is increased, and the heating process is achieved.

According to the process characteristics of electric thermal oil heating furnace, the high precision digital explicit temperature controller is selected to automatically start the optimal process parameters for PID temperature control. The control system is a closed-circuit negative feed system. The oil temperature signal detected by the thermocouple is transmitted to the PID controller, which drives the contactless controller and the output duty cycle in the fixed period, so as to control the output power of the heater and meet the heating requirements.

Post time: Nov-02-2022