Get us a free quote today!

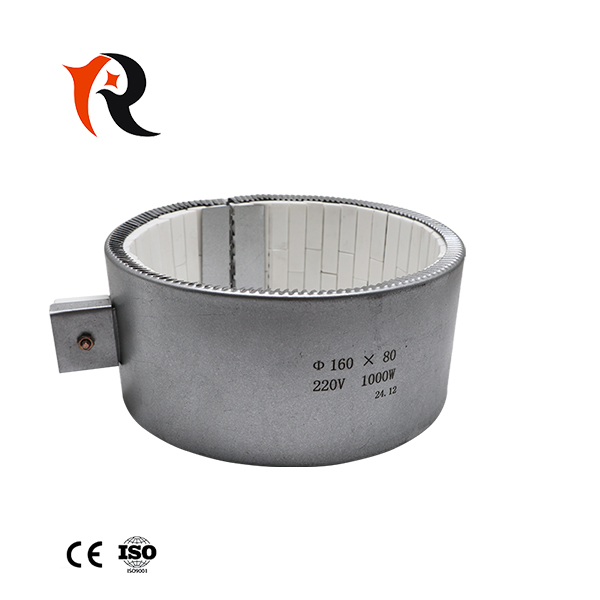

Ceramic Band Heater: Environmentally friendly equipment suitable for heating of extruders

Product Overview

The ceramic band heater is a specialized heating element designed for efficient, uniform heat transfer in industrial processes. Constructed with high-quality ceramic insulation and resistance wire, this heater delivers rapid heating, precise temperature control, and long-lasting durability. Ideal for heating cylindrical surfaces such as pipes, barrels, and mold nozzles, it is widely used in plastic processing, food production, chemical engineering, and metalworking industries.

Ready to find out more?

Key Features

1. Superior Heating Efficiency

- High Thermal Conductivity: Ceramic insulation ensures minimal heat loss, allowing the heater to reach operating temperatures quickly (up to 600°C) and maintain consistent heat distribution across the entire band surface.

- Energy-Saving Design: Low thermal inertia reduces warm-up time and energy consumption, making it cost-effective for continuous or intermittent use.

2. Robust Construction

- Durable Materials: Made with high-purity alumina ceramic (95% Al₂O₃) and nickel-chromium (NiCr) resistance wire, the heater withstands high temperatures, corrosion, and mechanical stress.

- Reinforced Casing: Optional stainless steel or Inconel sheaths provide added protection against abrasion, chemicals, and harsh environments.

3. Precise Temperature Control

- Even Heat Distribution: The spiral-wound resistance wire is evenly embedded in ceramic tiles, eliminating hot spots and ensuring uniform heating across the band.

- Compatibility with Controllers: Integrates seamlessly with thermocouples, RTDs, and PID controllers for accurate temperature regulation (±1°C precision).

4. Flexible Installation & Customization

- Adjustable Sizes: Available in diameters from 20mm to 1000mm and widths from 20mm to 300mm; custom sizes and shapes (e.g., split bands, flanged designs) are available for unique applications.

- Easy Mounting: Equipped with spring-loaded clamps, bolt-on brackets, or adhesive backing for secure attachment to cylindrical surfaces without drilling or welding.

5. Safety & Reliability

- Overheat Protection: Optional built-in thermal fuses or thermostats prevent overheating and ensure operational safety.

- Long Service Life: High-quality materials and advanced manufacturing processes result in a service life of 10,000+ hours under normal operating conditions.

Technical Specifications

|

Parameter |

Range/Details |

| Power Rating | 100W to 5000W (single-phase or three-phase options) |

| Voltage | 110V, 220V, 380V, or custom (AC/DC compatible) |

| Maximum Operating Temp | Up to 600°C (ceramic core); 500°C (stainless steel sheath) |

| Band Thickness | 6mm to 15mm (depending on power density) |

| Insulation Resistance | >100MΩ at 500V DC (cold state) |

| IP Rating | IP54 (standard); IP65/IP67 available for wet environments |

| Lead Wire | 1m fiberglass-insulated wire (custom lengths and connectors available) |

Applications

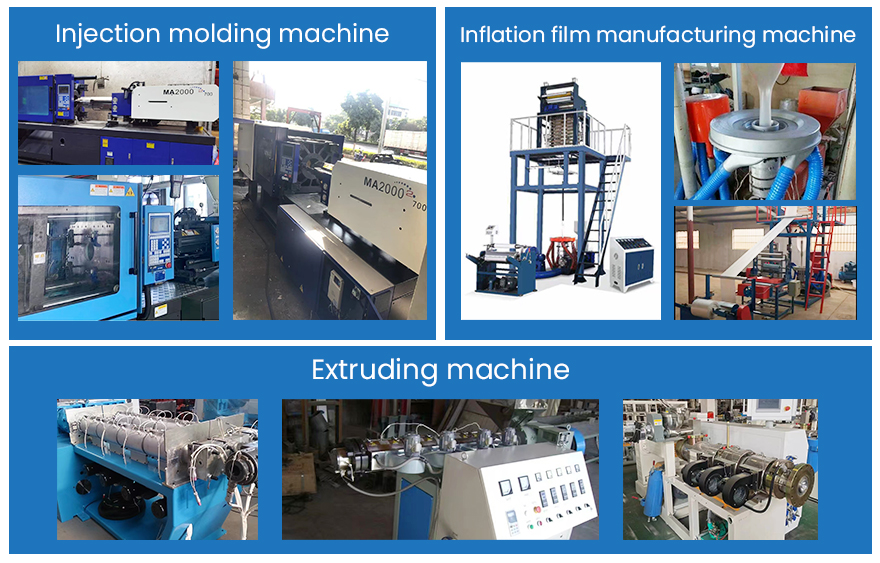

- Plastic Processing: Extruders, injection molding machines, and blow molding nozzles.

- Food & Beverage: Heating barrels for chocolate tempering, syrup warming, and pasteurization.

- Chemical Industry: Reactors, distillation columns, and pipe heating for viscosity control.

- Metalworking: Preheating molds, annealing, and curing processes.

- Laboratory Equipment: Heating mantles, autoclaves, and sample preparation devices.

How to order

Please provide the following information:

1.Vottage :380V, 240V, 220V, 200V, 110V can be customized.

2. Wattage: 80W, 100W, 200W, 250W can be customized.

3. Size: Length * width * thickness.

4. Whether there are holes. If so, it is necessary to provide the number, size and location of the holes.

5. Heat sensitive type: plug, screw, lead, etc.Step

6. Quantity

7.Other special requirements if you have them

Ceramic package with heater

1) Plastic bag + carton for belt heater

2) Wooden box for belt heater

Ceramic transport with heater

1) Express (sample order) or sea (bulk order)

2) Provide global shipping services

Application scenario

1. Injection molding/extrusion machine

2. Rubber molding/plastic process machinery

3. Mold and die head

4. Packaging machinery

5. Shoemaking machinery

6. Test equipment/laboratory equipment

7. Food processing machinery

8. Buckets with solids or fluids

9. Vacuum pumps and more...

Our Company

Yancheng Xinrong Electronic Industries Co., Ltd. is a manufacturer specializing in industrial heaters. For example, mica tape heater/ceramic tape heater/mica heating plate/ceramic heating plate/nanoband heater, etc. Enterprises to independent innovation brand, establish "small heat technology" and "micro heat" product trademarks.

At the same time, it has a certain independent research and development capability, and applies advanced technology to the design of electric heating products to create the best product value for customers.

The company is in strict accordance with the ISO9001 quality management system for manufacturing, all products are in line with CE and ROHS testing certification.

Our company has introduced advanced production equipment, precision testing instruments, the use of high-quality raw materials; Have a professional technical team, perfect after-sales service system; Design and manufacture various types of high quality heater products for injection molding machines, suction machines, wire drawing machines, blow molding machines, extruders, rubber and plastic equipment and other industries.