150kw Air Duct heater for Cotton Drying

Working principle

Air duct heater is mainly used for air heating in the duct, specifications are divided into low temperature, medium temperature, high temperature three forms, the common place in the structure is the use of steel plate to support the electric pipe to reduce the vibration of the electric pipe, the junction box is equipped with overtemperature control device. In addition to the control of the overtemperature protection, but also installed between the fan and the heater, to ensure that the electric heater must be started after the fan, before and after the heater added a differential pressure device, in case of fan failure, the channel heater heating gas pressure generally should not exceed 0.3Kg/cm2, if you need to exceed the above pressure, please choose the circulating electric heater; Low temperature heater gas heating higher temperature does not exceed 160℃; Medium temperature type does not exceed 260℃; High temperature type does not exceed 500℃.

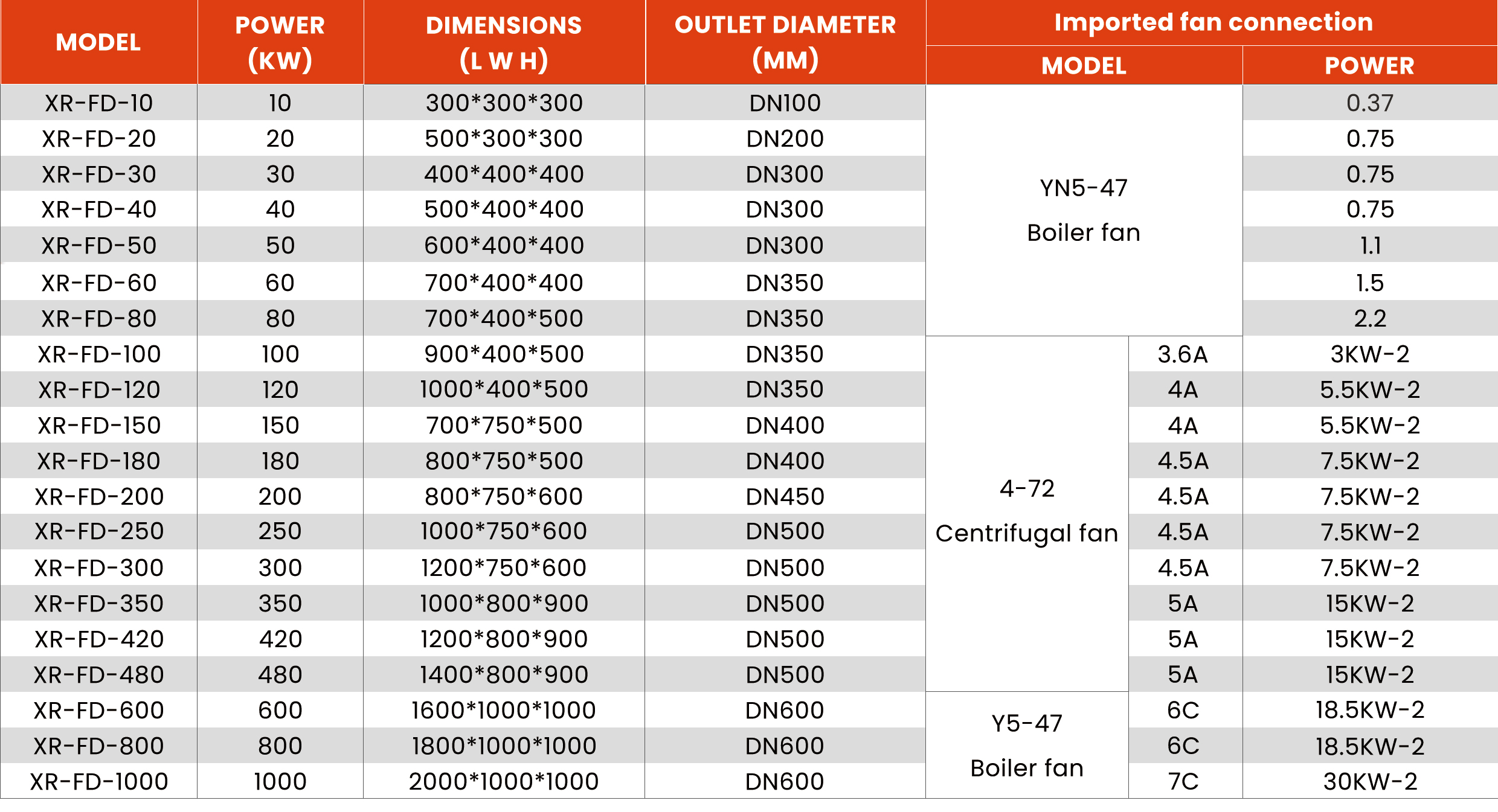

Technical Date Sheet

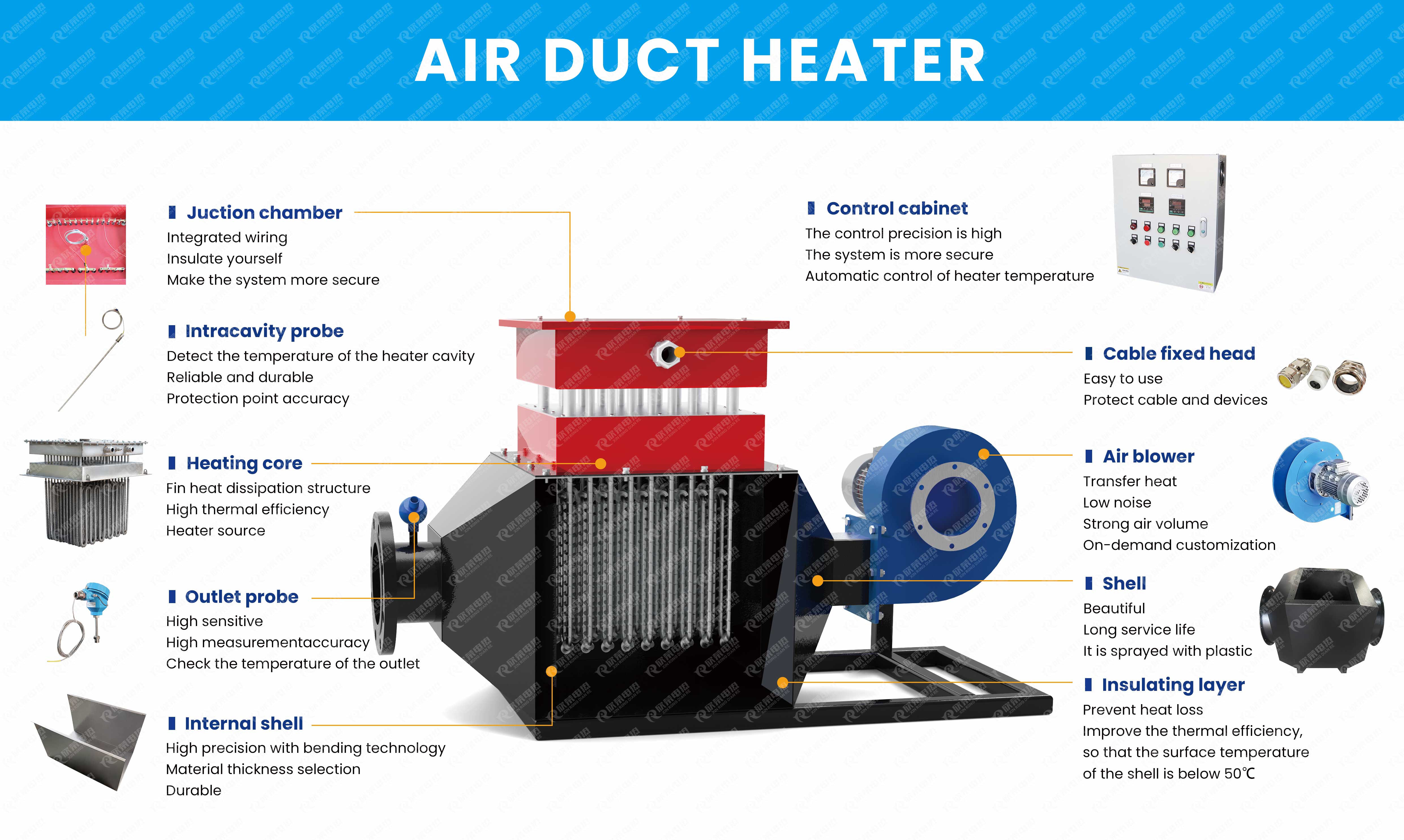

Product details display

Composed of electric heating elements, centrifugal fan, air duct system, control system, and safety protection

1. Electric heating element: core heating component, common materials: stainless steel, nickel chromium alloy, power density is usually 1-5 W/cm ².

2. Centrifugal fan: drives air flow, with an air volume range of 500~50000 m ³/h, selected according to the volume of the drying room.

3. Air duct system: Insulated air ducts (material: stainless steel plate+aluminum silicate cotton, temperature resistant to 0-400 ° C) to ensure efficient heat transfer.

4. Control system: contactor control cabinet/solid-state control cabinet/thyristor control cabinet, supporting multi-stage temperature control and alarm protection (over temperature, lack of air, overcurrent).

5. Safety protection: Overheating protection switch, explosion-proof design (Ex d IIB T4, suitable for flammable environments).

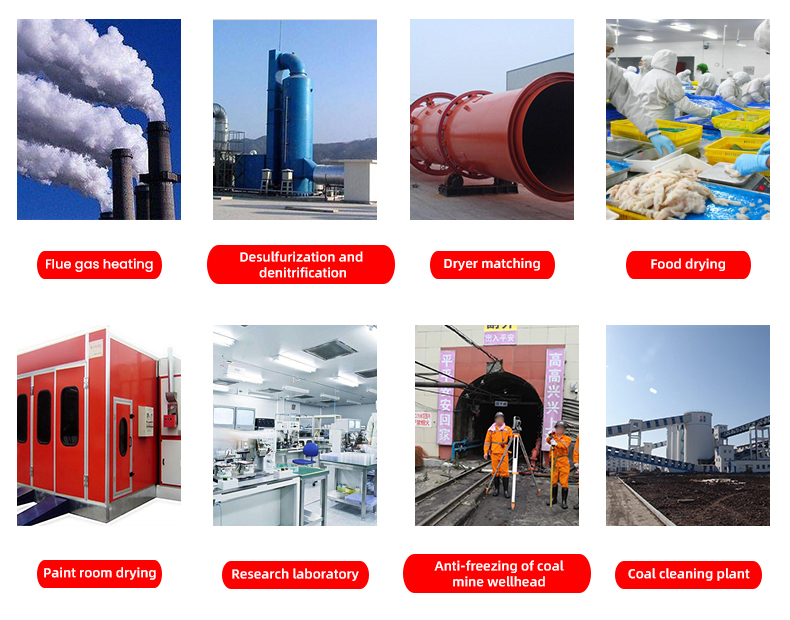

Product Advantage and Application

1. Hot air is evenly distributed to avoid local overheating or humidity

--Equal flow design: The guide plate or equal flow orifice plate inside the air duct ensures that the hot air evenly penetrates the cotton layer to prevent local overtemperature (damage to the fiber) or incomplete drying.

--Directional air supply: The position and angle of the air duct outlet can be flexibly adjusted according to the structure of the drying equipment (such as drying room, drum, conveyor belt), and targeted strengthening of weak drying areas.

- 2. Efficient heat energy utilization, reduced energy consumption

--Closed circulation system: The air duct can be connected to the waste heat recovery device to recycle the heat in the exhaust air and improve energy efficiency (energy saving can reach 20%~30%).

--Reduced heat loss: Insulated air duct can reduce heat dissipation and maintain a stable drying temperature.

3. Adapt to various drying processes

-- Batch drying (such as drying room):

--The air duct sends hot air from the bottom or side to penetrate the cotton pile, which is suitable for slow drying of high-moisture seed cotton.

--Continuous drying (such as conveyor belt):

--The air duct is combined with multi-stage heating zones to control the temperature in sections (such as rapid evaporation in high-temperature zone → slow evaporation in low-temperature zone) to avoid brittle cotton fibers

Customer use case

Fine workmanship, quality assurance

We are honest, professional and persistent, to bring you excellent products and quality service.

Please feel free to choose us, let us witness the power of quality together.

Certificate and qualification

Customer Evaluation

Product packaging and transportation

Equipment packaging

1) Packing in imported wooden cases

2) The tray can be customized according to customer needs

Transport of goods

1) Express (sample order) or sea (bulk order)

2) Global shipping services

If you want to know more about our products, please contact us !